PCM Microencapsulation: An Engineering Breakthrough for Thermal Energy Storage in the Borehole Battery™

Copyright © 2024 Philip C. Cruver

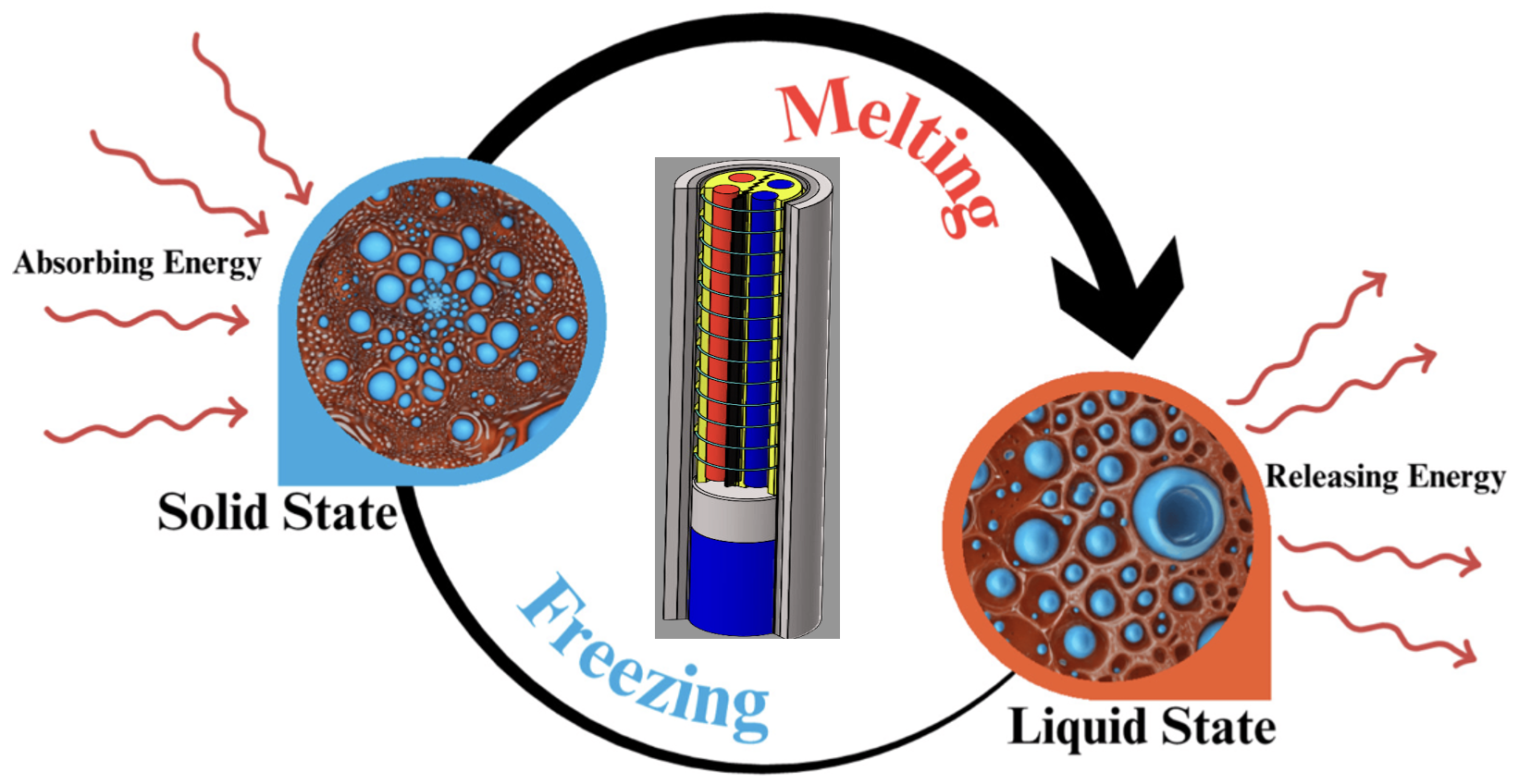

Phase Change Materials (PCMs) are unique substances that absorb and release thermal energy over time. By undergoing melting and solidifying processes, PCMs can store and dispense heat, making them invaluable for various applications in thermal insulation and thermal management. Their high latent heat capacity allows PCMs to harness heat energy efficiently during phase transitions, making them ideal for controlling heat transfer and achieving thermal objectives in engineering.

Thermal Energy Storage

Thermal energy storage technologies capture heat in a medium and release it later, like how batteries store and dispense electrical power. PCMs play a crucial role in thermal energy storage systems, which come in two main types: Sensible Heat Storage (SHS) and Latent Heat Storage (LHS). LHS is particularly advantageous as it can store and release significantly more heat energy across a given temperature difference. Effective PCMs must reliably change their phase with a given energy input and release this energy when the phase change reverses. Engineers continuously seek the best designs and PCMs for their systems, considering factors like the number of thermal cycles required and incorporating tools like forced convection for heat dissipation.

PCMs and Thermal Engineering

Effective PCM heat sinks can store thermal energy while maintaining a stable temperature. Engineers often place PCMs in hermetically sealed capsules or other enclosures to maximize their effectiveness. While absorbing heat via PCM is a straightforward concept, designing effective systems requires engineering expertise and careful selection of the right PCM for each application.

Types of Phase Change Materials

An ideal PCM scores high in heat of fusion, thermal conductivity, specific heat, consistent freezing behavior, and durability under repeated cycling. Other considerations include melt temperature, weight, corrosion resistance, and cost. Engineers customize formulations to operate at specific melting points and may use encapsulation to enhance performance. PCMs fall into three categories: organic, inorganic, and eutectic materials. Each type has its advantages:

Organic PCMs: Less prone to phase separation and corrosion.

Inorganic PCMs: Higher storage capacities and better thermal conductivity.

Eutectics: Combine two or more PCMs.

Microencapsulated PCMs for Borehole Battery™ Applications

Microencapsulation involves enclosing PCMs within microscopic capsules, typically ranging from micrometers to millimeters in size. This process creates tiny, uniform particles that can be mixed with other materials, allowing for more precise and efficient thermal management at a smaller scale. Microencapsulation is particularly useful in applications where uniform distribution and integration with other materials are critical.

Microencapsulated PCMs are particularly effective for enhancing the thermal characteristics of sand (silicon dioxide) as a thermal storage medium in small 7-inch diameter but deep 5,000 foot idle oil wells for converting them into efficient Borehole Batteries™. Microencapsulation provides several key benefits:

Enhanced Thermal Conductivity: By encasing PCMs in protective shells, engineers can improve the thermal conductivity of the surrounding sand. This ensures efficient heat transfer between the PCM and the well environment.

Stability and Durability: Microencapsulation helps protect PCMs from environmental degradation and chemical interactions with the surrounding sand material. This extends the lifespan and reliability of the PCM over many thousands of thermal cycles.

Controlled Phase Change: Microrencapsulated PCMs maintain a stable phase change process, providing consistent thermal performance. This is crucial for applications in deep oil and gas wells with temperature fluctuations.

Maximized Heat Storage: The microencapsulation process allows for precise control over the amount of PCM used, optimizing the heat storage capacity within the limited space of a small diameter borehole that is standard within an oil or gas well.

Reduced Maintenance: Microencapsulated PCMs require less maintenance compared to unencapsulated forms, as the protective casing prevents leakage and contamination, ensuring long-term operational efficiency.

The microencapsulation of PCMs represents a significant engineering breakthrough in thermal energy storage, particularly for innovative applications like the Borehole Battery™. By leveraging the unique properties of PCMs, engineers can design systems that efficiently manage and store thermal energy, providing sustainable and effective solutions for a variety of thermal management challenges. Microencapsulated PCMs are ideal to increase the thermal characteristics of sand in deep wells for converting idle assets into powerful thermal storage systems.